Accessories

We provide quality material handling and crane accessories for 25+ makes and models. Ranging from pendants and remote controls, to variable frequency drives, we have the equipment that will facilitate easy operation.

Pendant configurations depend on the functions of the equipment being operated.

Each push-button on the pendant controls an operating function of the crane system. The pendant can suspend from the trolley and hoist, which requires the operator to walk with and alongside the load, or on a separate sliding track system; in turn allowing the operator to move independently of the load

A pendant can also work in conjunction with a Variable Frequency Drive.

A VFD is used to vary the frequency of the motors controlling the motions, which allows for smooth acceleration and deceleration; an infinite control over speed.

The enclosure houses the electrical components of the crane and is rated by the National Electrical Manufacturers Association (NEMA) or the Canadian Electrical Manufacturers Association concerning the level of protection they provide, from the conditions in the surrounding environment.

Below is a list of the most common basic protection levels; CEMA/NEMA1, CEMA/NEMA 12 and CEMA/NEMA 4.

NEMA 1 standards to ensure your operators are protected from accidental contact or electrical shock. All of our equipment is enclosed, abiding by the highest safety standards.

Guarantees protection from indoor particles, such as dirt, dust, oil and water.

Is a combination of indoor and outdoor protection.

This safety standard requires enclosures that are capable of protecting controls from hosed-down, wet or outdoor environments, as well as indoor particles like dirt, dust and oil.

Radio Controls

We have a wide range of radio remote options for any crane and hoist need.

The radio control performs the same way as a pendant but operates using a radio frequency. The radio control incorporates many safety features and affords the operator a greater range of movement than a pendant. We offer the following alternatives:

Variable Drives

Variable drives are one of the greatest innovations for cranes in decades. They provide the following improvements:

Variable drives eliminate inrush current and reduces run current, improving the efficiency of motors. Inrush current is typically 5 to 8 times run current, so on a 20 Hp motor, at 480V, the inrush current can be as high as 220 Amps. Many industrial electrical meters measure peak current; your electrical bill for 220 amp will be significantly higher than for 25 amp.

Safety is a prime concern when moving large loads. Variable drives ramp speeds up and down, reducing dangerous load swing.

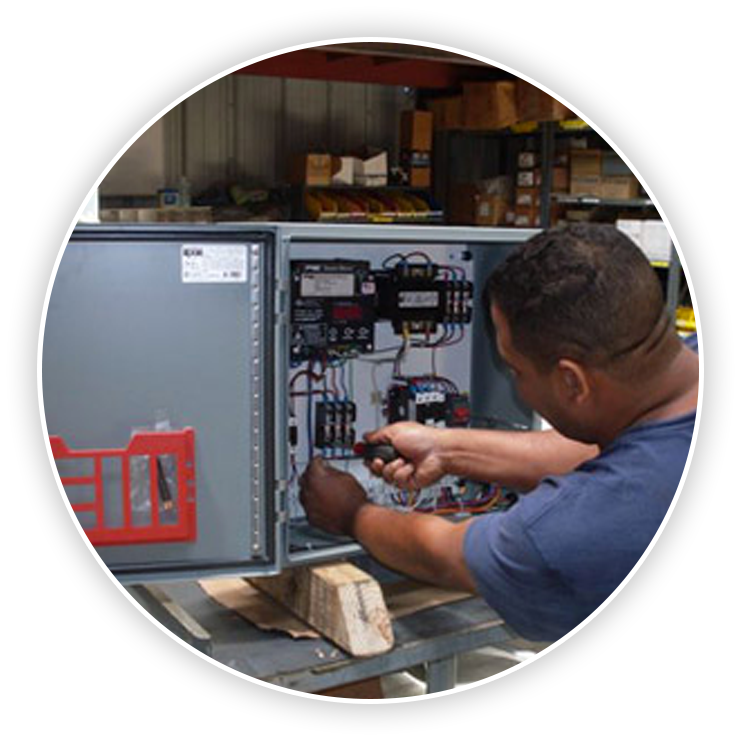

Controls

From replacement variable frequency drives to custom panels and automation, we’ve got everything you need for controls.

We have electrical engineers on staff to address all of your control needs. Why should you purchase your inverter or control panel from MHS?

- UL508A Certified

- Overload Capability – 300% starting torque

- Oversized Power Sections – Cooler operation and longer life

- Built in Braking Resistors

- Large, User Friendly Display

- Color and number coded wiring for easy troubleshooting, long life, and ease of use

Quick Quote Request

Simply fill out the form to the right to speak with an expert.